Environmental requirements are reshaping the electronics industry, presenting new challenges for businesses striving to remain compliant while maintaining efficiency and market access. These regulations, which cover hazardous substances like PFAS chemicals and EU POPs, demand proactive strategies to manage compliance risks, streamline supply chains, and enhance sustainability.

Tracking compliance is vital to meet regulatory requirements and protect your business. As regulations become more stringent, effective compliance monitoring minimizes risks and ensures public safety.

At Accuris, we understand the complex challenges electronics manufacturers face. Our latest enhancements to BOM Intelligence and Parts Intelligence are designed to address these challenges and transform them into competitive advantages.

This article delves into how environmental regulations transform the electronics sector, their impact on supply chains, key strategies to tackle compliance challenges, and how our latest product enhancements are crafted to turn these challenges into competitive advantages.

Understanding Compliance Monitoring

Keeping track of compliant materials is an indispensable part of a manufacturer’s toolkit, especially as rules surrounding hazardous substances like PFAS chemicals grow increasingly complex. Compliance monitoring ensures that products meet safety standards and adhere to the ever-evolving regulatory requirements, mitigating risks and protecting the company and its consumers.

The importance of compliance monitoring cannot be overstated. Regulatory frameworks such as PFAS, EU POPs, and TSCA are designed to minimize environmental and health risks posed by hazardous substances. Close monitoring of compliance helps manufacturers avoid inadvertently contributing to environmental damage or jeopardizing human health. With regulatory authorities tightening limits on substances like PFAS, the stakes are higher than ever.

Effective compliance monitoring programs require continuous assessment and adjustment. This dynamic process allows organizations to adapt to changes in risk profiles and regulatory landscapes. Teams must allocate time and resources to analyze parts data, identifying inconsistencies and gaps that could hinder compliance efforts. This proactive approach helps maintain compliance and preemptively addresses potential issues before they escalate.

Understanding and implementing robust compliance monitoring practices is crucial for any manufacturer aiming to thrive in today’s regulatory environment. These efforts safeguard operations, protect public health, and contribute to a safer, more sustainable future.

Key Regulatory Frameworks to Monitor

Navigating the regulatory maze is daunting yet essential for any organization. Understanding these frameworks is the foundation of effective compliance monitoring. Regulations such as PFAS, EU POPs, and TSCA protect the environment and human health by reducing the persistent damage caused by hazardous chemicals. The significance of these regulations extends beyond mere compliance; they are instrumental in safeguarding public health and ensuring environmental sustainability.

Key regulatory frameworks to monitor include PFAS regulations, EU POPs compliance requirements, and the TSCA and SCIP database mandates. Each framework has unique requirements and specific actions that organizations must adhere to, making it imperative to stay informed and proactive. These regulations help minimize environmental risks and improve human health by limiting exposure to toxic substances.

A thorough understanding of these frameworks enables organizations to take necessary actions and avoid severe repercussions of non-compliance with relevant laws. This foundation allows for a deeper exploration of each critical regulatory framework.

PFAS Chemicals Regulations

PFAS are synthetic chemicals found in many electronic components. The widespread use of these “forever chemicals” has led to significant PFAS contamination in the environment, raising serious concerns about human health and safety. Exposure to PFAS has been linked to various health issues, including kidney and testicular cancers, thyroid disease, and immune system dysfunction.

Toxic PFAS chemicals make PFAS testing essential to assess and manage these risks. The harmful impacts of PFAS pollution on public health and the environment have prompted regulatory efforts to limit the use of these chemicals and protect communities from exposure. The Environmental Protection Agency (EPA) plays a crucial role in regulating PFAS chemicals, setting stringent limits to reduce PFAS exposure.

EU POPs Compliance

The EU POPs (Persistent Organic Pollutants) regulations are designed to restrict the use of hazardous substances, including certain PFAS compounds. These regulations categorize substances into annexes that outline prohibitions, restrictions, and waste management requirements, ensuring comprehensive control over the lifecycle of these toxic chemicals. Non-compliance with these regulations can lead to severe penalties and impact market access.

TSCA and SCIP Requirements

The Toxic Substances Control Act (TSCA) and the Substances of Concern In Products (SCIP) database play pivotal roles in monitoring hazardous substances in production. These regulatory frameworks require companies to conduct regular assessments and report the presence of hazardous substances, ensuring continuous compliance and safeguarding public health.

Impacts of Environmental Regulations on the Electronic Component Supply Chain

Environmental regulations reshape the electronic component supply chain, presenting manufacturers with challenges and opportunities. These regulations, which aim to reduce the use of hazardous substances and promote sustainability, profoundly affect how companies operate and compete in the global market.

Material Restrictions and Substitution Requirements

One key impact of environmental regulations is the prohibition of hazardous substances. Regulations such as the EU POPs strictly limit the use of certain PFAS compounds, including perfluorooctane sulfonates (PFOS) and perfluorooctanoic acid (PFOA). This necessitates the development of safer alternative components, driving up research and development costs and potentially affecting product performance. Manufacturers are compelled to innovate and adapt to these changes, which can lead to the creation of more sustainable products.

Comprehensive Supply Chain Reporting Obligations

Some regulations impose detailed substance disclosure requirements on businesses, mandating them to report PFAS usage. This necessitates thorough audits of the supply chain to ensure compliance. Additionally, the Sarbanes-Oxley Act enhances transparency and accountability in financial reporting for publicly traded companies, ensuring a higher standard of compliance and reputation management. The SCIP database submissions require EU companies to provide data for articles containing substances of very high concern (SVHC) above 0.1% by weight. This ensures transparency and traceability, fostering trust among consumers and stakeholders.

Increased Compliance Costs and Operational Challenges

The need for compliance programs, comprehensive supply chain data collection, and product redesign to eliminate restricted substances significantly increases operational costs. Companies must allocate resources effectively to manage these requirements. Furthermore, replacing non-compliant components can lead to supply chain disruptions, causing delays and necessitating supplier renegotiations, impacting production timelines and overall efficiency.

Enhanced Environmental and Health Protections

By adhering to these stringent regulations, the electronics industry reduces environmental pollution and minimizes human exposure to these substances. This alignment with global sustainability goals protects the environment and enhances public health, demonstrating the industry’s commitment to responsible manufacturing practices.

Legal and Market Access Implications Due to Health Risks

Compliance with environmental regulations helps companies avoid hefty fines, such as those under TSCA, which can reach up to $48,512 daily for non-compliance. Furthermore, non-compliant products risk facing entry bans in key markets, potentially impacting revenue and damaging brand reputation. Thus, maintaining compliance is crucial for ensuring market access and sustaining competitive advantage in the global marketplace.

In conclusion, while environmental regulations pose significant challenges, they drive innovation and sustainability in the electronic component supply chain. By navigating these regulations effectively, companies can enhance their operational resilience, protect human health, and contribute to a more sustainable future.

Best Practices for Effective Compliance Monitoring

Preparation is paramount to achieving effective compliance monitoring. This includes building proactive compliance programs by staying ahead of regulations, tracking updates, and aligning processes early. Leveraging tools like BOM Intelligence can flag risks during product design stages, ensuring compliance from the outset.

Enhancing supply chain collaboration is also essential. Partnering with suppliers provides transparency into component materials while using integrated systems like Parts Intelligence, allowing efficient data sharing. This collaboration ensures that all parties are aligned and informed about compliance requirements.

Investing in sustainable innovation is another key strategy. By adopting safer alternatives to restricted substances, companies can future-proof their products and position sustainability as a competitive differentiator in the market. This approach meets regulatory demands and appeals to environmentally conscious consumers.

Lastly, leveraging advanced technology is crucial. Incorporating parametric search and custom filters enables quick identification of compliant parts, streamlining the compliance process and reducing exposure to risks. Adhering to these best practices helps organizations maintain robust compliance monitoring programs and safeguard public health.

The Role of Accuris in Navigating Compliance

Accuris plays a pivotal role in helping electronics manufacturers navigate the complex landscape of environmental regulations with our latest enhancements to BOM Intelligence and Parts Intelligence.

These solutions are specifically designed to directly integrate critical regulatory data, including PFAS, EU POPs, TSCA Section 6(h), and SCIP, into your workflows. This integration empowers your business to confidently manage regulatory challenges by providing:

Comprehensive Regulatory Coverage

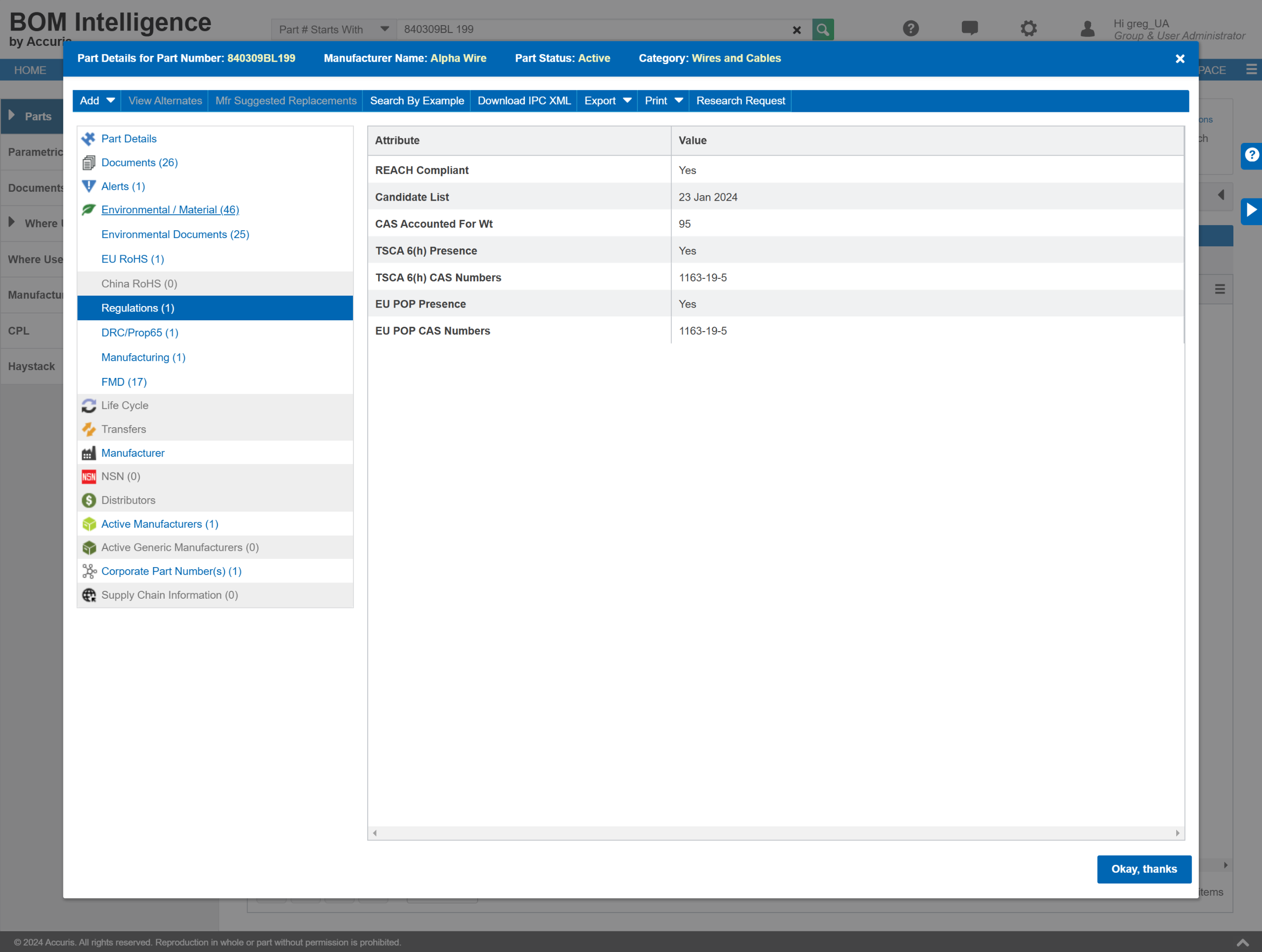

- New Environmental Attributes: Quickly identify components containing regulated “forever chemicals” like PFAS and access detailed CAS numbers for TSCA and EU POPs compliance.

- Integrated Data Access: Seamlessly view compliance information across BOM and part details details, ensuring quick and efficient access to critical data.

- Comprehensive Insights: Stay informed about regulated substances and compliance requirements to mitigate risks effectively.

Enhanced Supply Chain Visibility

- Identify components with hazardous substances swiftly and assess safer alternatives.

- Leverage real-time insights into part availability and compliance to minimize disruptions and maintain continuity.

- Optimized Workflows: Utilize custom layouts and filters to streamline and enhance compliance processes.

Streamlined BOM Analysis

- Simplify SCIP submissions and ensure full compliance with TSCA and EU POPs regulations.

- Use exporting tools to analyze and optimize your Bill of Materials (BOM), improving operational efficiency and reducing compliance costs.

These enhancements allow for the quick identification of components containing regulated PFAS substances, facilitating easier compliance with regulatory standards. Additionally, Accuris ensures seamless access to SCIP numbers required for EU reporting, streamlining the compliance process.

By integrating these attributes across BOM and part details, Accuris simplifies your compliance processes and ensures accessibility where you need it most, ultimately contributing to a safer and more sustainable industry.

Benefits of Maintaining Compliance

Maintaining compliance with regulatory standards offers numerous benefits for organizations. Adhering to regulations helps businesses avoid costly penalties and fines, which can significantly impact their financial health. Compliance also fosters trust among stakeholders, enhancing the organization’s reputation and customer loyalty.

Furthermore, compliance helps organizations better manage risks and safeguard operations, preventing disruptions arising from non-compliance issues. Staying compliant also facilitates smoother international trade by conforming to global standards, opening up new markets and opportunities for growth.

Non-compliance with regulations can lead to severe consequences, including fines, market access restrictions, and damage to the company’s reputation. Maintaining compliance ensures organizations protect themselves and contribute to a safer, healthier environment.

Taking the Lead in Environmental Compliance with Accuris

The evolving regulatory landscape doesn’t have to be a roadblock; it can be a pathway to growth, sustainability, and market leadership. At Accuris, we combine cutting-edge technology with deep industry expertise to empower your business with:

- Risk Mitigation: Identify and address compliance risks before they can impact operations, ensuring smooth business continuity.

- Sustainability Leadership: Make informed decisions that reduce environmental impact and drive your organization toward a greener future.

- Operational Efficiency: Streamline workflows and enhance time-to-market, giving your business a competitive advantage.

Our solutions are crafted to meet the demands of today’s regulatory environment while preparing you for tomorrow’s challenges. By integrating reliable data, intelligent tools, and seamless workflows, we assist businesses in reducing compliance efforts, making informed sourcing decisions, and maintaining their competitive edge.

Stay ahead of regulations and lead with confidence. Explore the enhanced environmental attributes of BOM Intelligence and Parts Intelligence today and strengthen your commitment to a sustainable, compliant future.

Would you like to see how these updates can transform your business? Contact us for a demo or consultation.