What is Supply Chain Risk Management for electronic parts, and what tools are available to help tackle it?

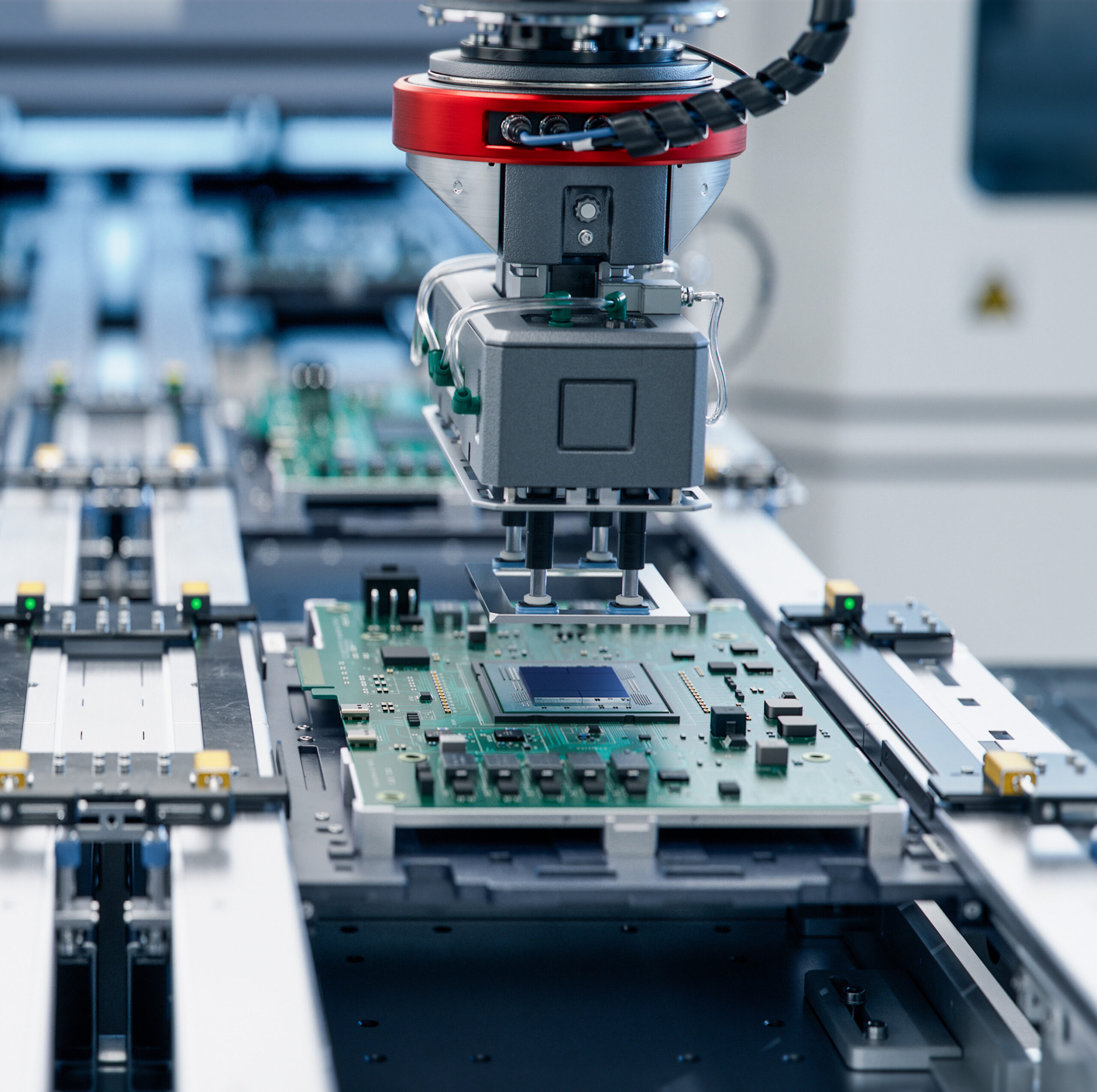

Electronic product manufacturers are dependent on increasingly complex supply chain networks. Manufacturers are investing in their Supply Chain Risk Management (SCRM) practices and tools to ensure a stable supply throughout the lifecycle of their electronic products.

Companies no longer consider only their nearest neighbor as their supply chain but the whole network of business activities, reaching all the way upstream to raw material extraction. These supply chains have grown increasingly complex and are often influenced by a variety of forces including environmental regulations, geographic location of supply chain actors, export controls, and economic forces. Companies that effectively manage these supply chain complexities enjoy fewer disruptions and higher sales and margins. Companies that fail to effectively manage their supply chains often find themselves running from one supply disruption to the next resulting in significant revenue impacts.

A 2021 study found supply chain disruptions cost companies with global operations an average of $184 million USD per year. U.S. companies in this group were especially hard hit with supply disruption costs averaging about $228 million USD per year [1]. The adverse effects of supply disruption on revenue are true for electronic products too, and perhaps more severe given the complexity of modern electronic products and their dependence on rare natural resources with limited regional availability.

Fortunately, there are established methods to help mitigate risks related to disruptions in the electronic parts supply chain. These methods – a combination of practices, services, and resources – are commonly called Supply Chain Risk Management (SCRM). SCRM for an electronic parts supply chain includes sourcing from multiple suppliers and manufacturers, identifying part vulnerabilities, and forecasting available supply. This optimizes critical part inventory and provides a quick process for addressing supply chain disruptions.

SCRM strategies rely on access to current and accurate electronic parts data, historical data, and analysis tools. However, not all databases are equal. The challenge to building a robust database is harmonizing the specifications of electronic parts across the industry and creating a single source of truth – 1 database with consistent, reliable information. Normalizing common specifications is a common method used to do this, but sometimes more rigorous approaches are needed when adding parts to a database.

Thus, the last crucial element of a SCRM system is the software and analytical practice used to extract insights from a database. Accuris Parts Intelligence (a database of 1.1B+ electronic parts) meets these requirements, helping you build a dependable SCRM system that is accurate, complete, current, and robust.