Primer on the Most Prominent Material Compliance Requirements for Electronic Products

Modern electronic products are subject to a large and evolving number of material compliance requirements. They expand in terms of substance restrictions, reporting requirements, and record keeping requirements. They vary by region (Europe, U.S., Mainland China, etc.) and by product type (medical devices, toys, industrial equipment, etc.). Some regulations have exemptions which expire after certain timeframes and only apply to certain applications, so it’s a complex job to stay on top of all these product level regulations.

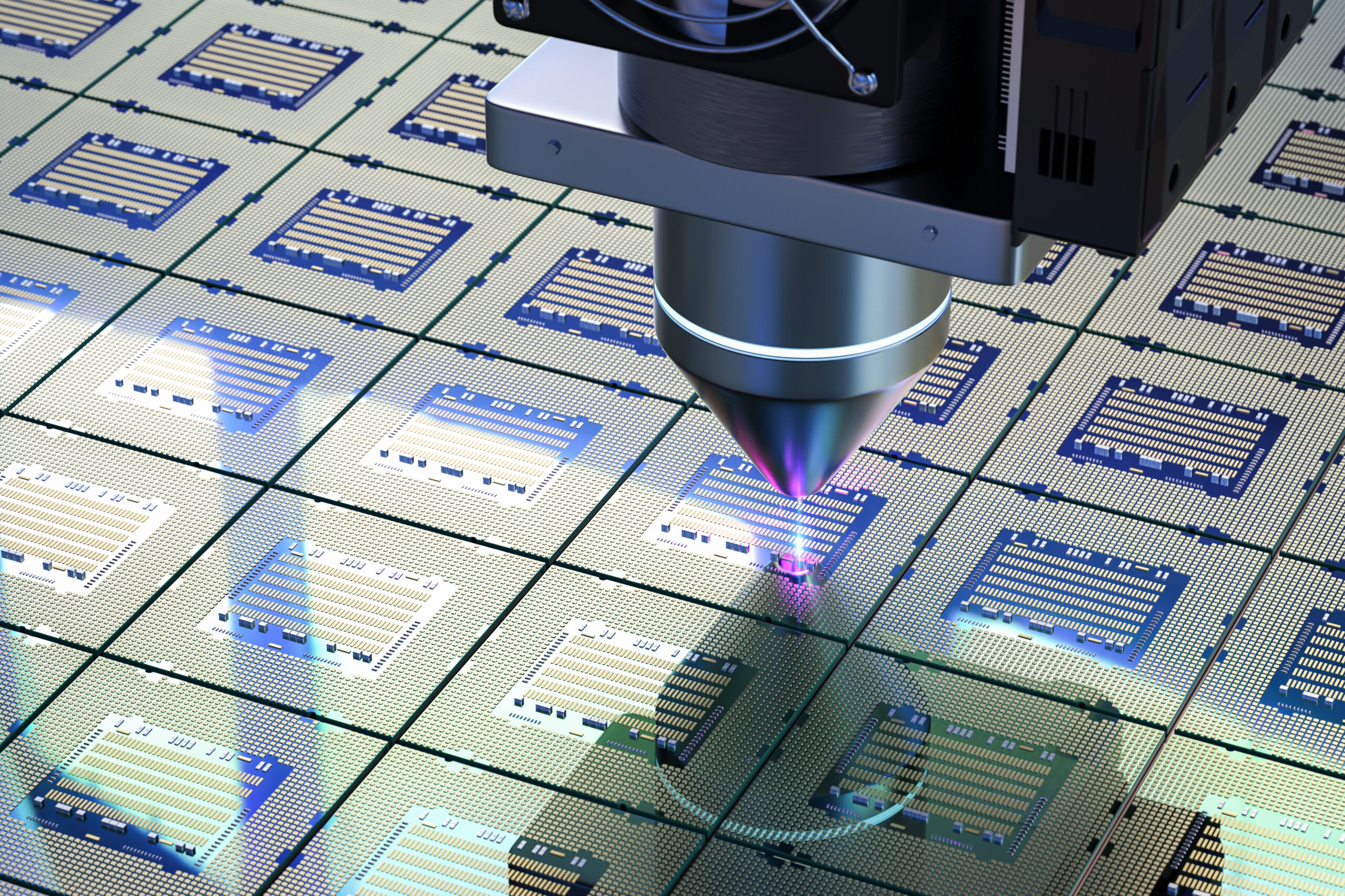

When electronic product manufacturers look to comply with the regulations, they typically look at all the parts, materials, and substances they’re using. They’ll consider each part and need to determine whether that part is compliant with all the regulations of concern. Of course, it’s best to have this part information and use it during the part selection process – but many companies have products that have already been designed and need to be evaluated. The best industry tools—like Accuris BOM Intelligence, support both of these requirements.

Material compliance regulations are part of what industry refers to as ESG—Environmental, Social and Governance. Regulations drive many of the requirements in this area, but product manufacturers may also need to comply with customer specific requirements.

This article (and the next few articles) will look at the major regulations that product manufacturers are dealing with, and provide a high level summary of each – along with a variety of resources for you to further investigate these material compliance regulations.

REACH

REACH is a safety regulation managed by the European Chemicals Agency (ECHA) with the intended goal of minimizing the risk to human health and the environment from chemical substances. It puts the burden on the chemical industry to ensure substances are safe by requiring a thorough registration process. Some chemical manufacturers choose not to register substances if their sales volumes are low and can’t justify the registration process expense. Electronic product manufacturers with operations in Europe need to pay attention to avoid dependencies on process chemicals that do not get registered and are essentially obsolete in Europe.

Electronic product manufacturers—called downstream users—need to be aware of the chemical substances they use directly in their products or that are in parts and materials they use. Some substances are banned outright (Restricted substances listed in REACH Annex XVII ), others can be used if they are under certain annual volume thresholds or if the manufacturer receives authorization to use them (authorization substances are listed in REACH Annex XIV). Others known as SVHC (Substances of Very High Concern) may be used but must be reported down the outbound supply chain (manufacturers’ customers) to ensure safe use. These SVHC are listed on the ECHA site1 and are also known as candidate substances for authorization. Most SVHC will become authorization substances and then restricted substances.

REACH is a horizontal regulation that applies to all companies, contrasting with EU RoHS, which applies to Electronic Products only. REACH is a regulation that directly applies in EU countries whereas EU RoHS is a directive which is transposed into individual EU countries’ regulations.

EU RoHS and China RoHS

RoHS (Restriction on Hazardous Substance) regulations around the world are based largely on the EU’s RoHS directive that went into effect over twenty years ago. The original EU RoHS (EU Directive 2002/95/EC) restricted six hazardous substances (lead, cadmium, mercury, hexavalent chromium, PBBs and PBDEs) known to be used in electrical and electronic equipment (EEE). This original RoHS also sought to address hazardous substances in the waste stream by requiring separate handling of waste EEE (WEEE) and setting targets for WEEE collection, recovery, and recycling.

In 2011, RoHS was recast to focus on hazardous substance restrictions (RoHS 2) and to a separate regulation focusing on WEEE. The RoHS Recast simplified the regulation in a manner that allowed easier management and updating through a series of Annexes: Categories of EEE covered (Annex I), Restricted Substances (Annex II), Exemptions (Annex III), Exemptions specific to medical devices and monitoring and control instruments (Annex IV).

The RoHS recast made RoHS compliance an EU CE marking (Conformité Européenne) requirement. Manufacturers are required to draw up technical documentation that includes showing how their products comply with RoHS, draw up an EU declaration of conformity, and attach the CE mark to their products, shown below:

RoHS is a living regulation and continues to evolve as exemptions are added and expire, additional substances are restricted such as the four phthalates (DEHP, BBP, DBP, and DIBP) added to the Restricted Substance Annex (EU Directive 2015/863). It should be noted that some in industry loosely refer to EU 2015/863 as “RoHS 3”, but this isn’t technically accurate, and we anticipate a true RoHS 3 in the future.

China RoHS is closely related to RoHS but has some key differences. China RoHS is based on the same original six substances as EU RoHS and is planning on adding the remaining four phthalates covered under EU RoHS (DEHP, BBP, DBP, and DIBP). China RoHS doesn’t actually ban use of the substances. Rather, China RoHS requires labeling indicating the presence of the substances above thresholds in a specific tabular form and doesn’t recognize exemptions like in EU RoHS. Labeling requirements also include providing the Environmental Friendly Use Period (EFUP) symbol indicating none of these substances above threshold concentrations (green symbol with an “e” inside a chasing arrow circle) or the actual number of years before any of the substances could “leak” out (orange symbol with the number of years inside a chasing arrow circle) as the examples show.

UK RoHS

The current UK RoHS is based on and is similar to EU RoHS. The UK requires a UK Declaration of Conformity, an associated Technical File showing how the product complies, and putting a UK Conformity Assessed (UKCA) marking on products.

European Union SCIP (Substances Of Concern In Products)

Relatively new requirements in the EU Waste Framework Directive (WFD 2018/851) require suppliers to report on the SVHC contained in their products. This information is meant to improve user safety during the products useful life and to improve worker safety at waste treatment facilities by providing access to information on the presence and location of hazardous substances in products in the waste stream. As such, the information in the SCIP database is available publicly to consumers, waste operators, and enforcement personnel.

As of January 2021, companies supplying articles containing REACH candidate list SVHC in concentrations above 0.1% must submit information on those articles to the SCIP Database maintained by ECHA (European Chemical Agency). As of February 2, 2022, ECHA reports there are over 7 million article notifications from almost 7,000 companies.